Design-Tested Frozen Vaccine Shippers: Ensuring Reliable Cold Chain Transport

Transporting vaccines isn’t just about getting them from one place to another—it’s a matter of life and death. Imagine a fragile vial journeying across hundreds or even thousands of miles, all while needing to stay at specific temperatures to remain effective. This is where frozen vaccine shippers come into the picture. They are specially designed packaging that ensure that these precious doses maintain their integrity during the entire delivery process. With innovation in technology and materials playing vital roles in how we protect vaccines, understanding the importance of these shippers seems more crucial than ever—especially as we work to improve healthcare logistics for everyone.

The temperature range of our frozen vaccine shipper packaging is -20°C and -80°C, lasting up to 48 hours.

EPS Frozen Shippers

| Shipper | Corepack Inside Dimensions* | -70°C or Below** | -60°C or Below** | -20°C or Below** |

|---|---|---|---|---|

| 867 EPS | 4 x 2¾ x 2⅞ | 26.00 | 28.50 | 38.00 |

| 1086 EPS | 6 x 413⁄16 x 2 | 37.25 | 41.50 | 57.00 |

| 12109 EPS | 8 x 6¾ x 4⅞ | 33.50 | 38.25 | 52.25 |

| 121213 EPS | 8 x 8¾ x 6⅞ | 36.25 | 41.50 | 60.25 |

| 201314 EPS | 17⅛ x 9⅞ x 9¼ | 33.25 | 41.50 | 53.25 |

| *Corepack = available payload area | **Duration in hours | |||

Cotton Frozen Shippers

| Shipper | Corepack Inside Dimensions* | -70°C or Below** | -60°C or Below** | -20°C or Below** |

|---|---|---|---|---|

| 1086 Cotton | 6 x 413⁄16 x 2 | 37.00 | 40.25 | 56.50 |

| 12109 Cotton | 8 x 6¾ x 4⅞ | 44.00 | 47.00 | 66.75 |

| 121212 Cotton | 8 x 8¾ x 6⅞ | 35.50 | 41.50 | 52.25 |

| *Corepack =available payload area | **Duration in hours | |||

About Design-Tested Frozen Vaccine Shippers

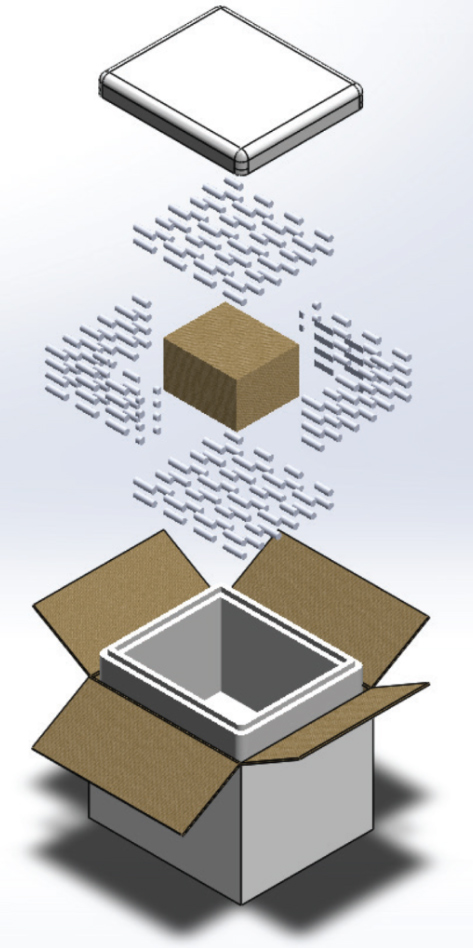

Frozen vaccine shippers are specialized packaging solutions that ensure the integrity of temperature-sensitive products, such as vaccines, during cold chain transport. Key features include various sizes for different payloads, sustainable construction from insulation materials like EPS (expanded polystyrene), and multi-component designs that maintain product temperatures over 24 to 48 hours.

A pivotal reason behind utilizing design-tested frozen vaccine shippers lies in their ability to maintain stable temperatures throughout the shipping process. With the majority of vaccines requiring temperatures between -20°C and -80°C for optimal efficacy, having reliable shipping solutions has never been more crucial.

Navigating the complexities of cold chain logistics requires sophisticated solutions capable of enduring harsh transit conditions while adhering to regulations designed to ensure public safety.